Powder coated aluminum sliding window profiles

At the same time, the thermal break technology incorporated into high-quality aluminum window frames prevents heat loss, thereby reducing energy consumption and contributing to a lower carbon footprint At the same time, the thermal break technology incorporated into high-quality aluminum window frames prevents heat loss, thereby reducing energy consumption and contributing to a lower carbon footprint

At the same time, the thermal break technology incorporated into high-quality aluminum window frames prevents heat loss, thereby reducing energy consumption and contributing to a lower carbon footprint At the same time, the thermal break technology incorporated into high-quality aluminum window frames prevents heat loss, thereby reducing energy consumption and contributing to a lower carbon footprint aluminium slim profile windows.

aluminium slim profile windows.

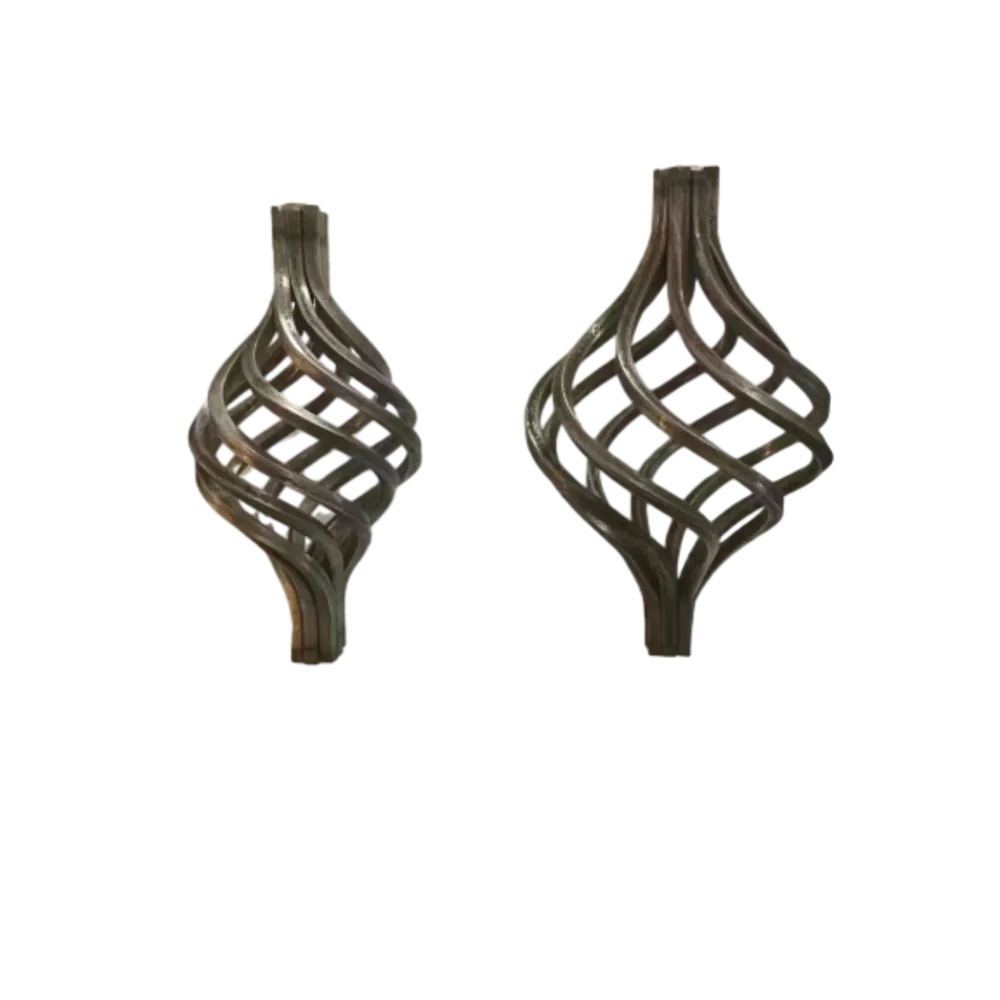

cast iron collars. This helps to save time and labor costs, making them a practical choice for busy work sites.

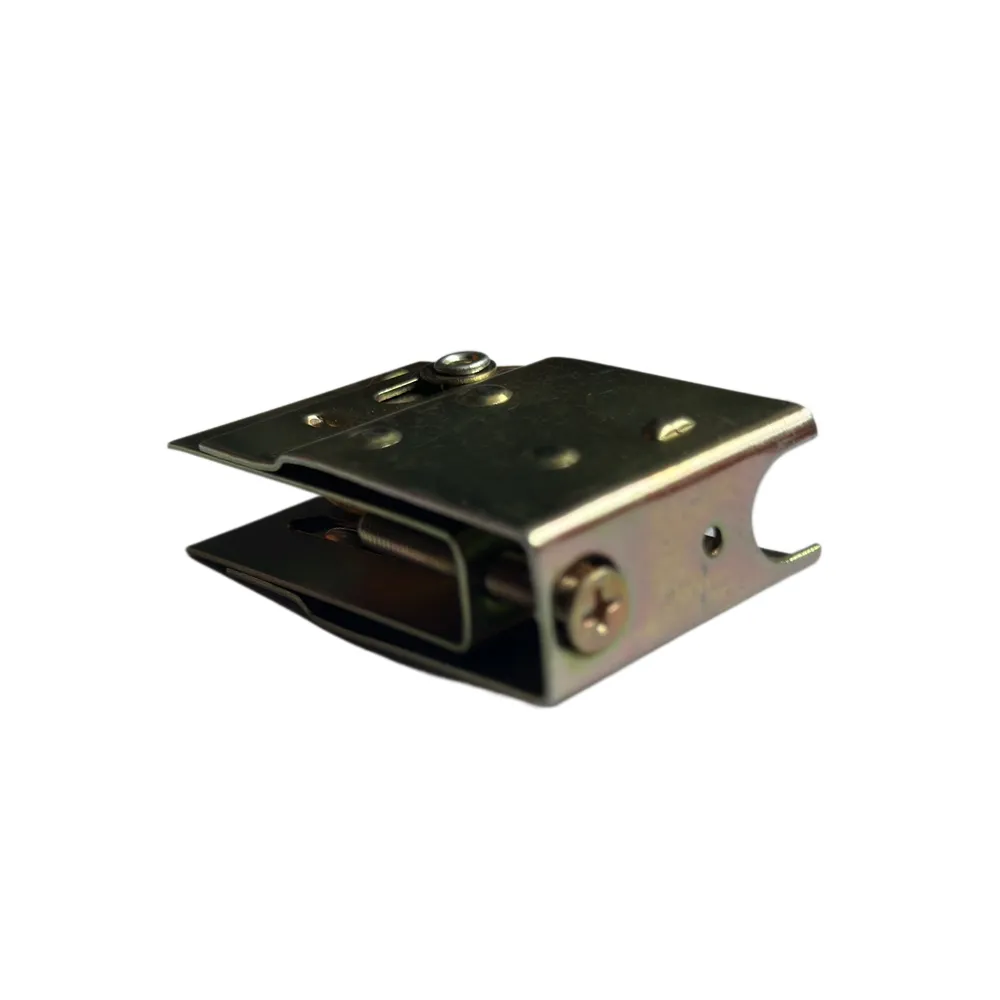

Surface Treatment

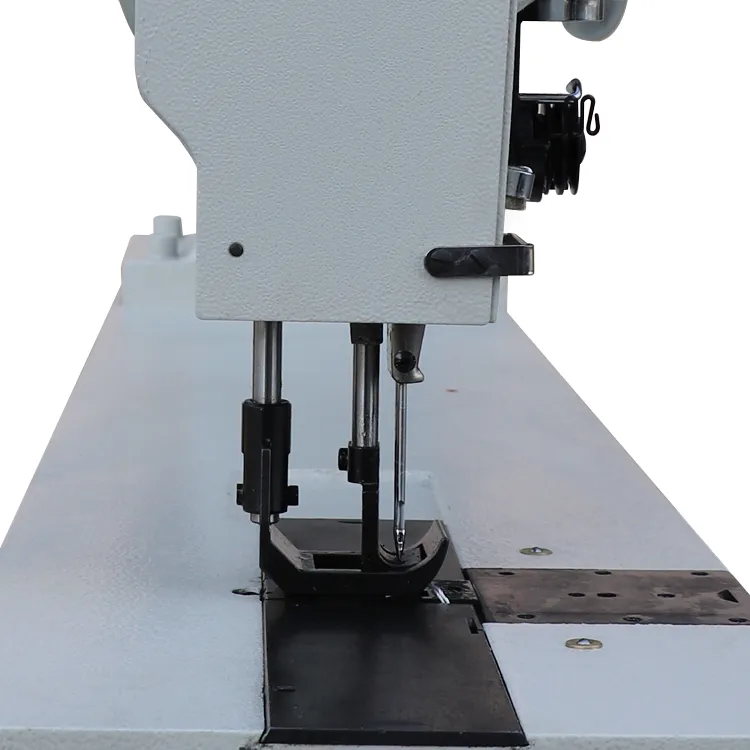

Thanks to the sliding window design, adjusting the lug nuts is a breeze Thanks to the sliding window design, adjusting the lug nuts is a breeze

Thanks to the sliding window design, adjusting the lug nuts is a breeze Thanks to the sliding window design, adjusting the lug nuts is a breeze